3D printing in-depth

Written by: Markus Lunzer, Simon Sayer, Øyvind Halaas and Otto Paans

The technology of the INCITE consortium partner UpNano GmbH from Vienna, Austria, allows to print the immune niches with great accuracy. UpNano has developed the NanoOne platform, a compact multiphoton lithography (MPL) device along with the custom control software Think3D, as well as a large range of photopolymer materials, allowing to substantially improve the fabrication throughput of MPL. This 3D-printing technology combines the high precision of two-photon polymerization (2PP) with the possibility to dynamically change the dimensions of the focal point on demand, resulting in an increase of the throughput by a factor of up to 100. The improved printing speed allows for much faster prototyping, shorter development cycles and even small-scale serial production. This enables new possibilities in micro-manufacturing and leading the innovation of two-photon polymerization.

Figure 1: The NanoOne is a compact ultrafast high-resolution 2PP 3D printing system.

What is two-photon polymerization (2PP)?

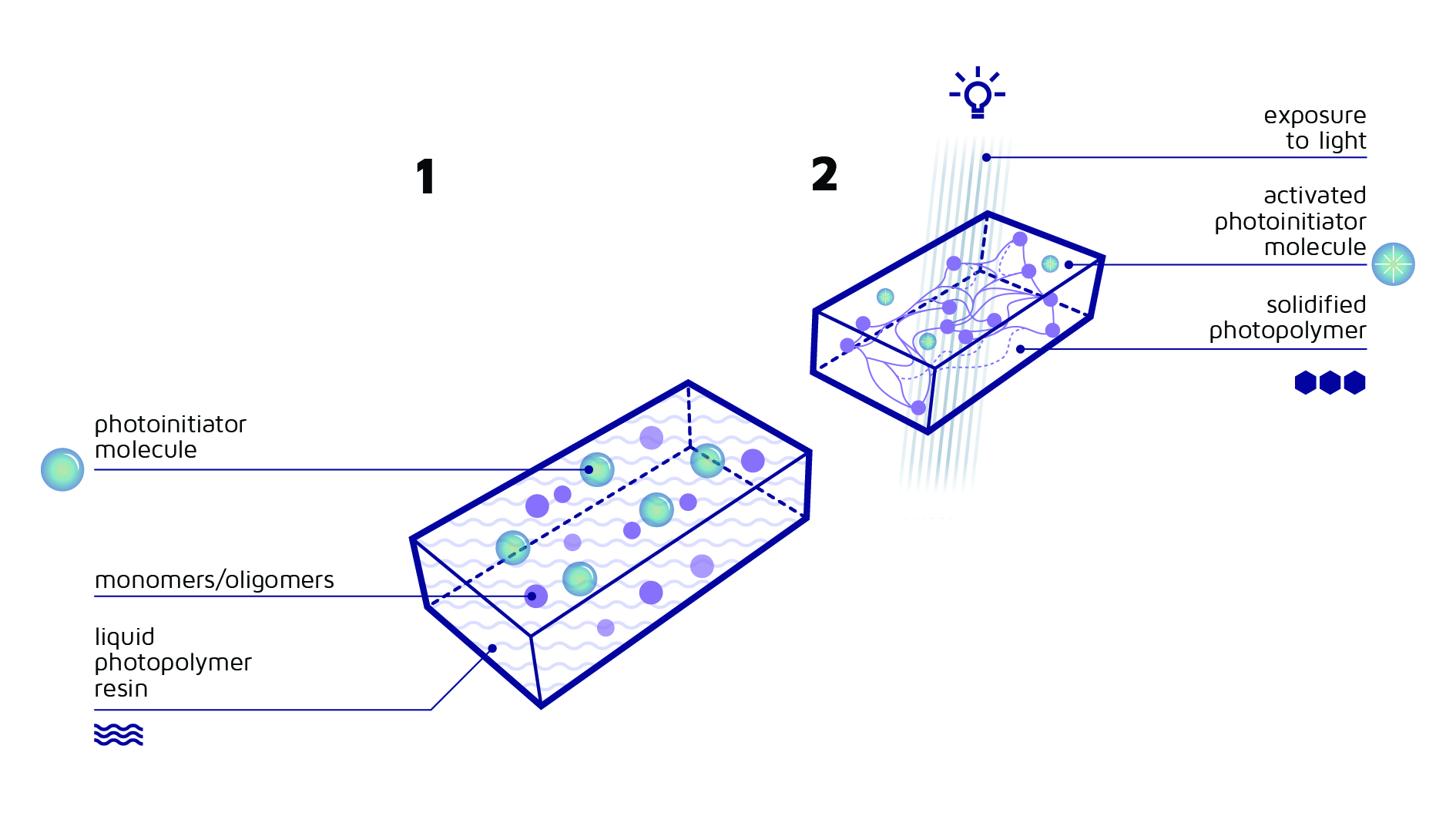

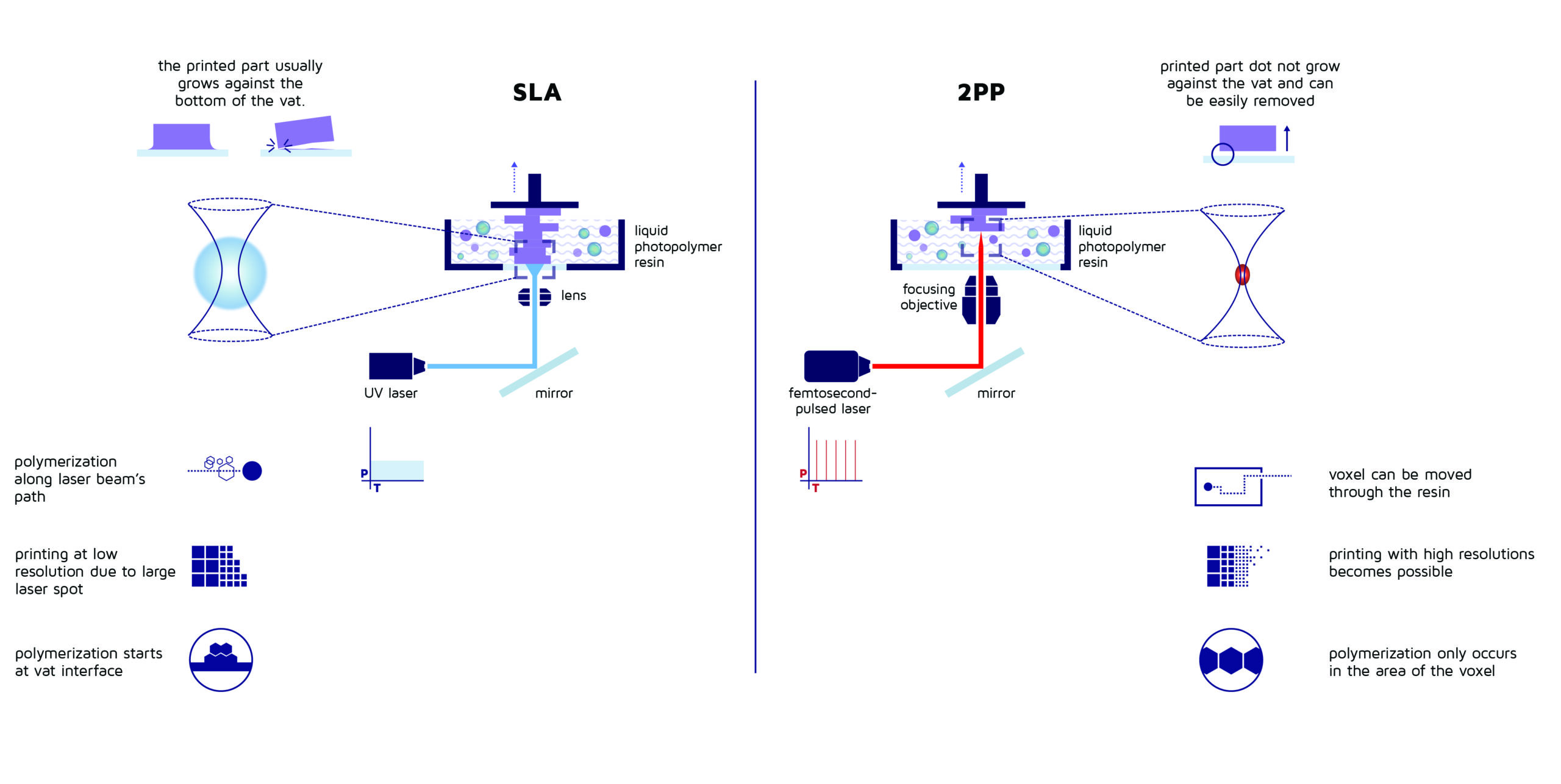

In resin-based 3D-printing (e.g. stereolithography or SLA) a photosensitive liquid prepolymer is irradiated with high energy light. Specific light-sensitive photoinitiator molecules, which are tailored to the wavelength of the light, are excited upon absorption of light and thus initiate a polymerization reaction.

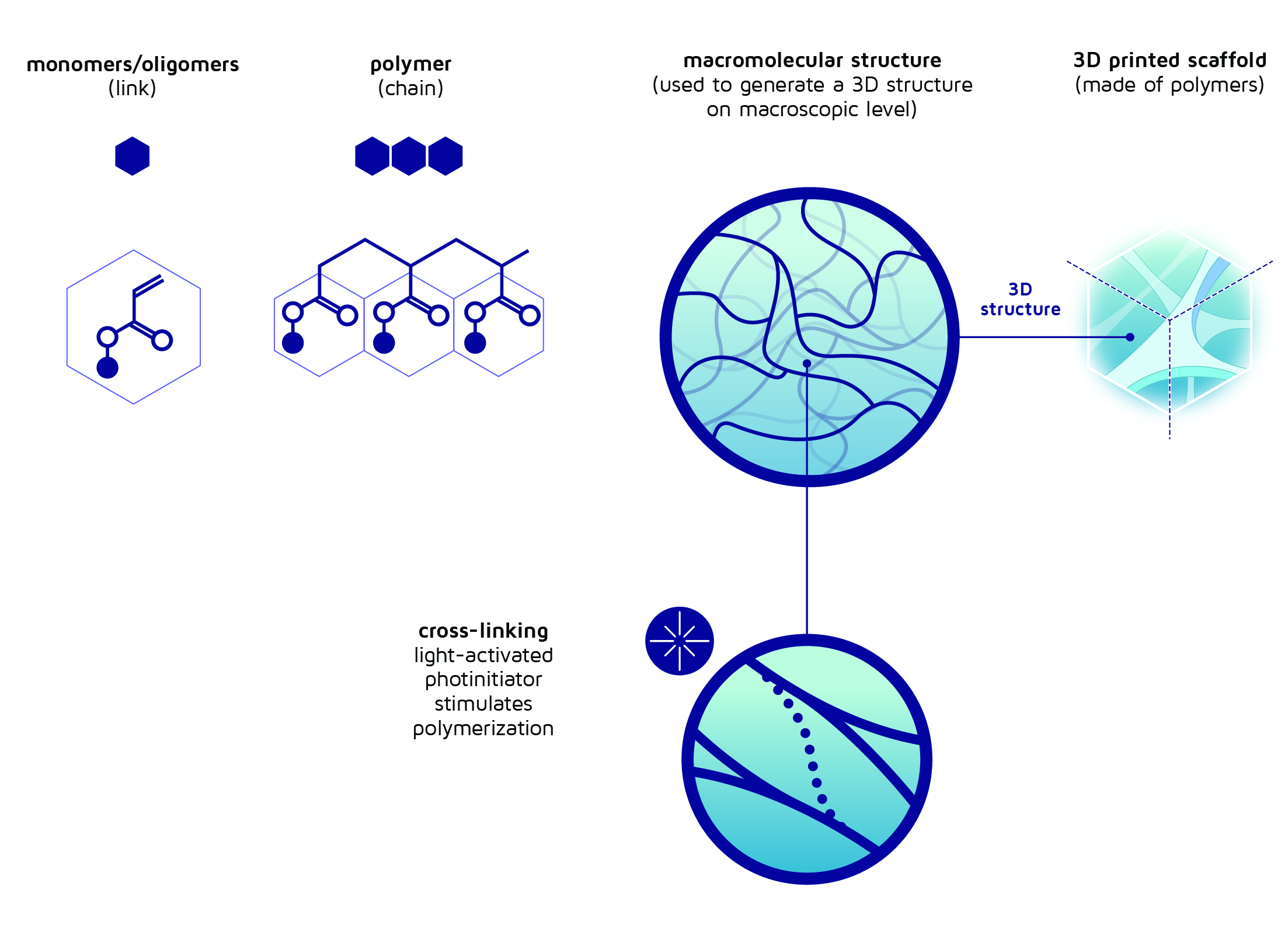

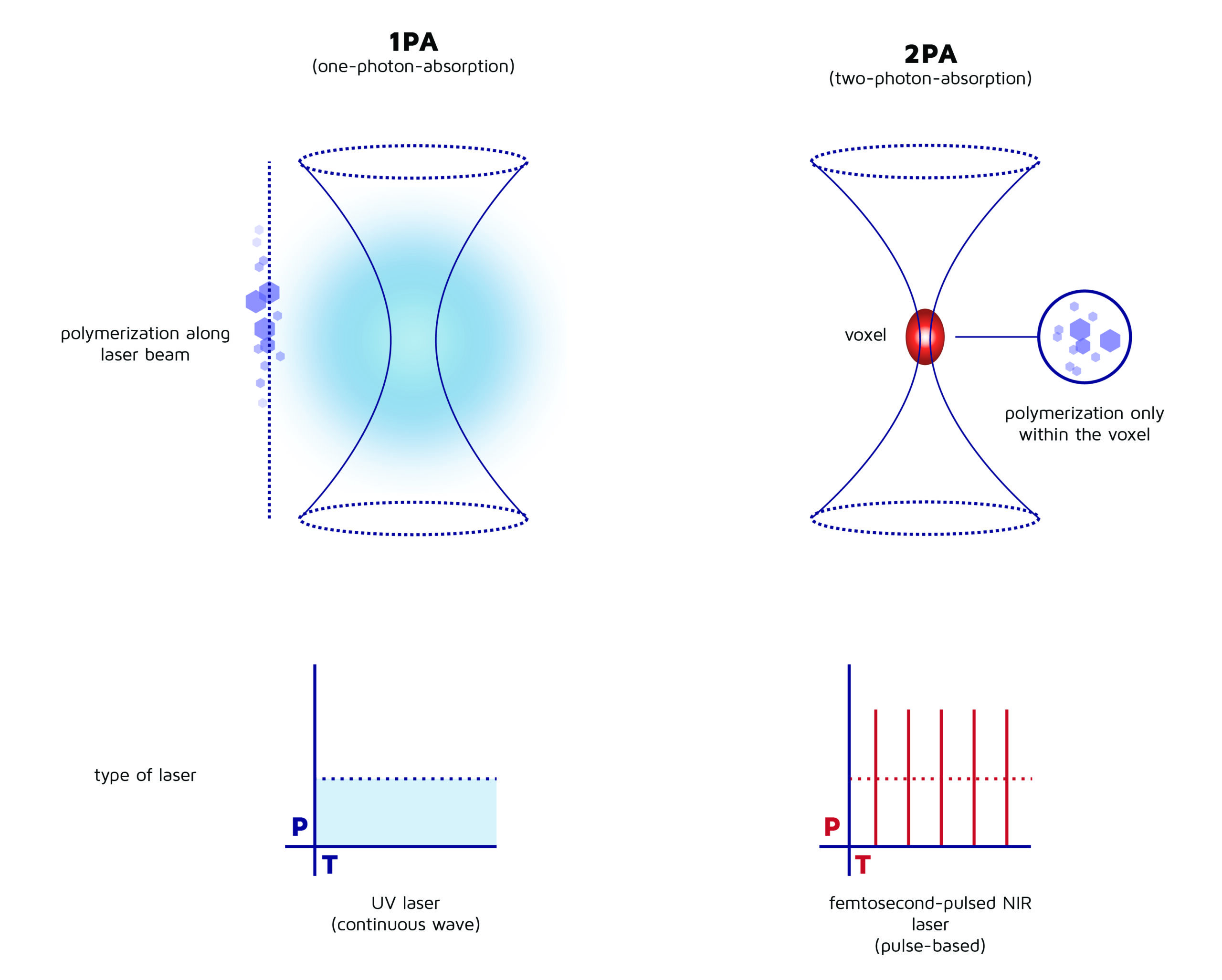

Polymerization is a chemical reaction in which the resin consisting of smaller molecules (so-called monomers, oligomers or pre-polymers) cure into macromolecules which result in a solid polymer. Through localized irradiation, complex 3-dimensional objects of solid polymer can be created from the resin. In a linear, or one-photon absorption (1PA) process, the photoinitiator molecules absorb photons with sufficient energy for excitation and then cause polymerization to occur along the entire path of light in the resin.

Figure 2: A liquid photopolymer resin consists of monomer, oligomer and photoinitiator molecules. The resin solidifies when the photoinitiator molecules are excited by the influence of specific light.

Figure 3: Polymers are macromolecular chains composed of monomers and oligomers that form the "building material" for the 3D-printed scaffold structure. The process of photo-polymerization is set off by light interacting with photoinitiator molecules. Cross-linking solidifies and further strengthens the mechanical properties of the material.

In contrast, two-photon absorption (2PA) is a non-linear process. Here, a single photon does not have sufficient energy to excite the photoinitiator molecule. However, under special circumstances – such as provided within the NanoOne – specific photoinitiator molecules can absorb a pair of photons within a very short time frame of a few femtoseconds (10-15 s) and become excited. Since a 2PA process requires two photons to be present at the same location simultaneously, the probability of such an event is inherently low, meaning that 2PA hardly ever occurs under natural circumstances. However, ultrashort pulsed laser light, which is tightly focused through a microscope objective, can be used to induce 2PA.

Figure 4: Under natural circumstances, the 1PA process (left) occurs, in which a single photon is absorbed by the photoinitiator molecule. However, this is a relatively unselective process and thus unsuitable for high-precision 3D-printing. Therefore, we use a laser with a longer wavelength and focus the light into a voxel, so that the 2PA process (right) occurs. This requires the absorption of 2 photons to reach the desired energy level, but reduces the volume of polymerization due to its rare probability.

Due to its nonlinear nature, the volume of the 2PA is confined to the focal spot of the laser light, the so-called voxel. Outside of the voxel the absorption probability decreases rapidly. Consequently, when the laser is focused into a two-photon sensitive liquid resin, highly localized two-photon polymerization (2PP) occurs.

Apart from providing a very high resolution, this method also allows to freely move the voxel through the resin to fabricate free standing structures. For this reason, delicate objects can be produced in closed vessels, such as cell culture dishes or microfluidic chips. Since the 2PP process is set off by the photoinitiator molecules in the focused laser beam, there is no need for a physical instrument to enter the closed volume.

An important advantage of the highly localized 2PP process is the fact that the printed structure does not polymerize on the material vat since the focal spot is placed above a transparent window, creating an optical polymerization dead zone. In contrast, the SLA process requires an additional step after every single layer in which the printed object has to be torn loose from the bottom of the vat. This step is time-consuming and limits the geometries of the parts, as fine structures could rupture.

Figure 5: While in the case of conventional resin-based 3D-printing (e.g. stereolithopgraphy/SLA) curing of the photopolymer resin occurs along the whole light path, in two-photon polymerization (2PP) the reactive curing zone is confined to the small voxel, allowing real 3D-printing within microfluidic devices. Additonally the focal point is maintained above the transparent window, preventing polymerization against the bottom of the vat.

What is innovative about UpNano’s technology?

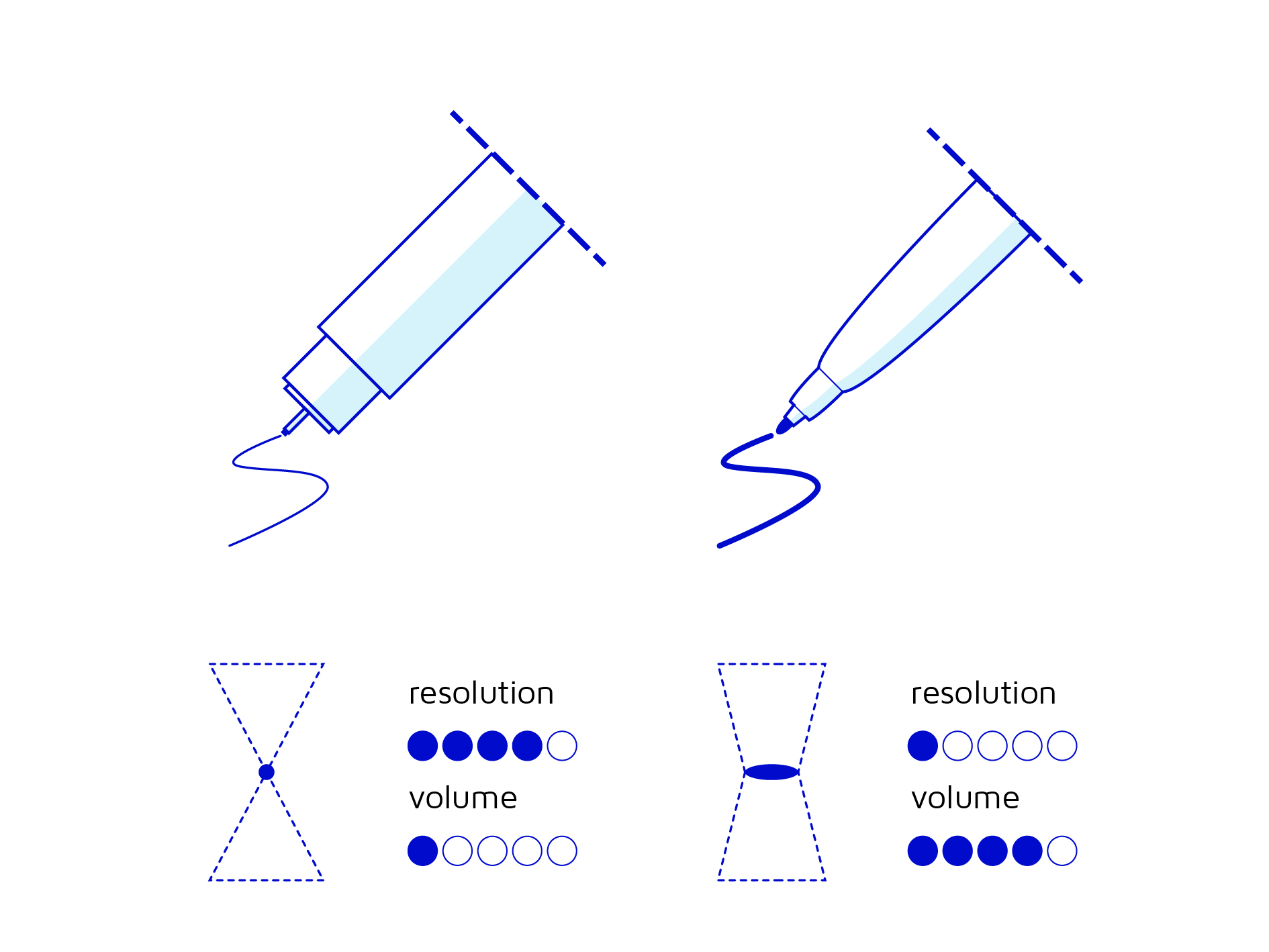

The 2PP technology permits to create very high-resolution microstructures, which is crucial when it comes to the fabrication of delicate features such as the immune niche. UpNano developed a patented process called “Adaptive Resolution” to modify the size and shape of the voxel to match the required resolution. Consequently, the scaffold of the immune niche can be produced much faster. This renders the fabrication of the large number of immune niches needed for INCITE economically feasible.

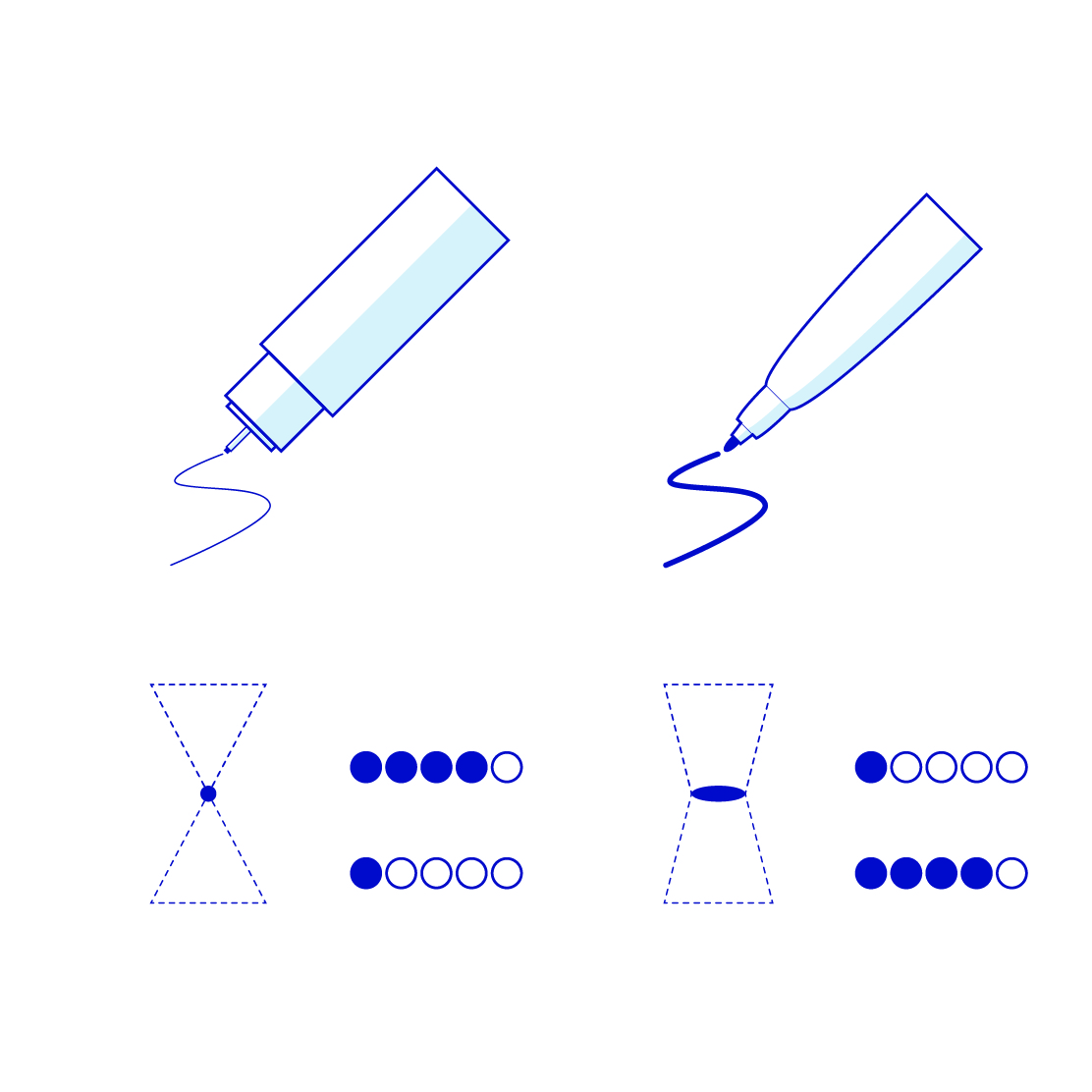

The Adaptive Resolution can be illustrated by comparing it to a thin liner pen, that can be switched to a marker or felt pen on demand. While the thin liner pen allows for high precision with low throughput, the marker permits high throughput polymerization at the cost of resolution.

Figure 6: The “Adaptive Resolution” technology permits to dynamically tune the size and shape of the voxel in real time during a print job to maximize the throughput in accordance with the actual resolution requirements. The “liner pen” setup allows for printing high-resolution segments, while the “marker” setup permits high throughput.

How can UpNano’s technology be used to support Immune Niches for Cancer ImmunoTherapy Enhancement (INCITE)?

Within the INCITE project, we create an artificial immune niche that mimics the native immune niche in the body, which can be used to create and/or select the fittest CAR-T cells to be used for immunotherapy.

To do so, specially tailored 3D-microfluidic elements will be fabricated into pre-existing microfluidic chips, which are later populated with a co-culture of selected cells. 2PP is the only micro-manufacturing technique that permits printing a complex 3D-dimensional object within a closed microfluidic chip. After 3D printing the microfluidic element, residual uncured resin is rinsed, and the procedure for seeding the immune niche with cells can be started. UpNano develops special 2PP photopolymers which are biocompatible and do not interfere with imaging of cells through microscopy. This way, the development of the cells can be monitored closely and without visual “noise”.

Due to this sophisticated 3D fabrication technology, the research team will be able to generate a multitude of custom microfluidic devices that support CAR-T cell sorting and culturing. The short fabrication time is crucial for the success of the INCITE project, allowing for rapid prototype cycles and custom batch production.

Outlook: What else can be achieved with 2PP?

2PP is a very versatile microfabrication technology. It allows fabrication of polymeric parts with smallest features below the micrometer range. However, with UpNano’s vat printing technology it is also possible to print larger functional parts of up to 40 mm in height. Commonly parts are produced from solid or elastic polymers. Nevertheless, by using certain post-processing steps, also final parts made of metal or even glass can be produced from specially tailored resins. Moreover, it is also possible to process hydrogels by 2PP for biomedical or cell-culture applications. Using the NanoOne Bio platform in combination with specific bio-inks even permits 3D printing in the presence of living cells, offering great potential for future tissue engineering and drug screening applications.

Video: In using a material vat, which is placed atop of the microscope objective, parts of up to 40 mm in height can be 3D-printed with the NanoOne.